- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

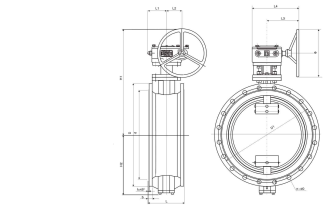

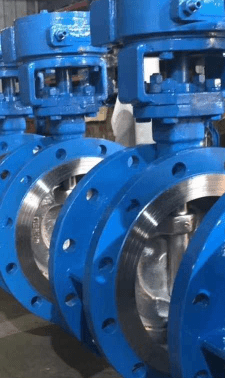

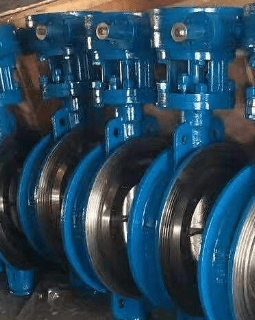

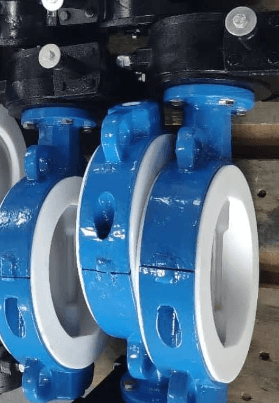

Butterfly Valve Suppliers in Saudi Arabia: Compact and Efficient Flow Control

Middleeast valve is the leading Butterfly Valve Suppliers in Saudi Arabia. It is a crucial component in fluid control systems, designed to regulate the flow of liquids or gases. Its primary parts include a disc, a shaft, and an actuator.

Working- the disc, typically circular, is positioned within the pipe and can pivot on the shaft. When the actuator is activated, it rotates the disc to either open or close the valve. The degree of rotation determines the flow rate.

Types:

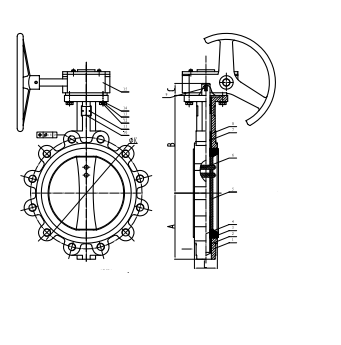

1)Wafer Butterfly Valve

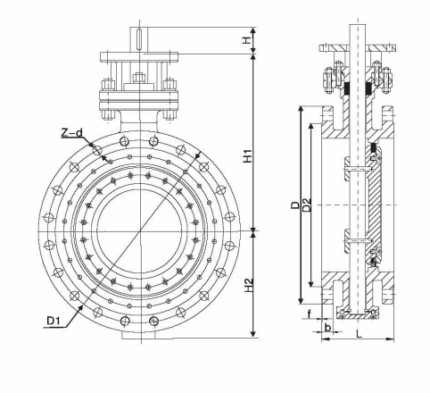

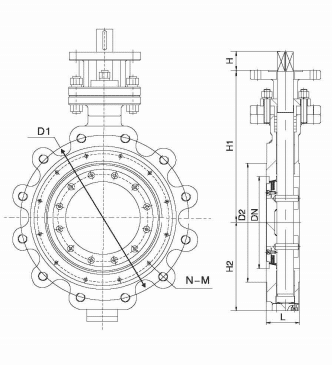

2)Flanged Butterfly Valve

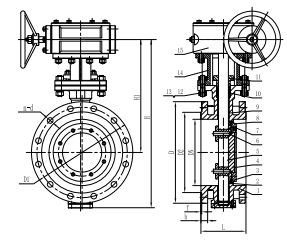

3)Triple Eccentric Butterfly Valve

4)Double Offset Butterfly Valve

5)Triple Offset Butterfly Valve

6)Lug Butterfly Valve

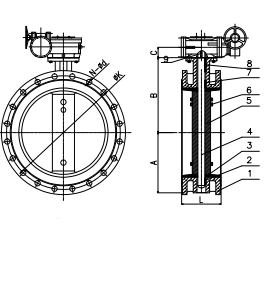

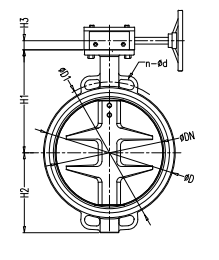

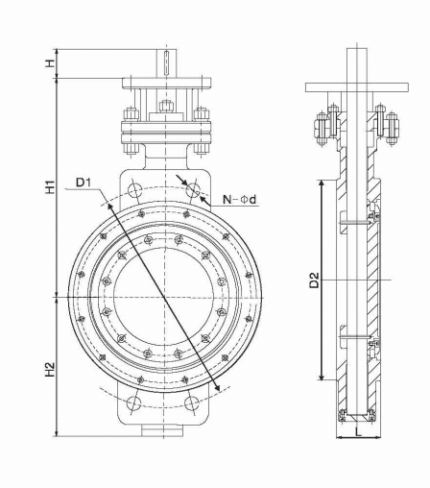

Key Parts of Butterfly Valve:

1)Valve Body: Where all the parts inside are accommodated.

2)Disc: It rotates in order to regulate the flow.

3)Shaft or Stem: It is the part to which the handle or actuator and disc are attached.

4)Seat: Provides a close fit to avoid leaks.

5)Actuator/Handle: Used for manual or automatic operation.

Advantages:

1)Their streamlined and light construction.

2)Low torque requirements and quick operation.

3)Simple to install and moderately cost-effectiveness.

4)Best suited for pipes with a large diameter.

Industries:

1)Chemical Industry

2)Oil and Gas Industry

3)Petrochemical Industry

4)Energy Industry

5)Marine Industry

6)Automobile Industry

Description:

Body Material: Cast Carbon steel (WCC, WCB, WC6), Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F31L, F91], DUPLEX STEEL and Super duplex Steel (F51,F53, F55) , Cast iron, Ductile Iron.

Size – 2” – 48”

Class- 150 to 300; PN 6 – PN 25

Ends- Wafer, flanged, lug

Operations- Lever operated, gear operated, pneumatic actuated and electric actuated.